Flow-Tek provides a wide range of Explosion Proof 3-Piece Stainless Steel Ball Valves. They are suitable for emissions free severe service, elevated and semi-cryogenic temperatures as well as high cycle applications. These valves have a double body seal design and stem packing protection, making them ideally suited for fire safe applications.

Body & End Pieces

Stainless steel 316 is used for the body of the 2-piece ball valve and the seats and seals are made from PTFE (Teflon). A fused epoxy coating protects the casting and prevents mineral deposits from attacking the seating and sealing areas. This helps the 2-piece valve maintain its integrity and elongates its life.

A 2-piece trunnion ball valve features a hollow, perforated shaft, or trunnion, that connects the stem to the body on one end and the seat on the other. The trunnion is secured to the valve body by heavy duty trunnions that are welded to each other for durability.

To test the trunnion for leaks, you need to open the valve, apply about 50 to 1000 PSI of air pressure while wearing ear and eye protectors, and pour water into the seat area until it covers the ball. Then, look for bubbles. If you find them, the seat has a leak. Retest with a different seat until you cannot detect any leaks.

Seats & Seals

As the valve is operated, the angular flat on the bottom of the valve stem mechanically wedges against the sphere and forces it tightly pressed against the seat to achieve a seal. This design provides bubble tight shutoff even at high pressure.

Unlike solenoid valves, ball valves are a better choice for some media with particulates, since the wiping motion of the ball across the seats tends to clear away debris that can get stuck in solenoid valves and cause clogs. They are also a more reliable choice for fail-safe applications because they act like normal shutoff devices and don’t rely on electricity.

Designed for sanitary environments, this full port, direct mount sanitary ball valve is ideal for steam, hot/cold water and numerous gas applications. It features a CF8M Stainless Steel valve body and 316 SS ball, Grafoil stem & body seals, a weld end or extended weld end, an ISO 5211 mounting pad for easy actuator installation and a Ta-Luft self adjusting stem.

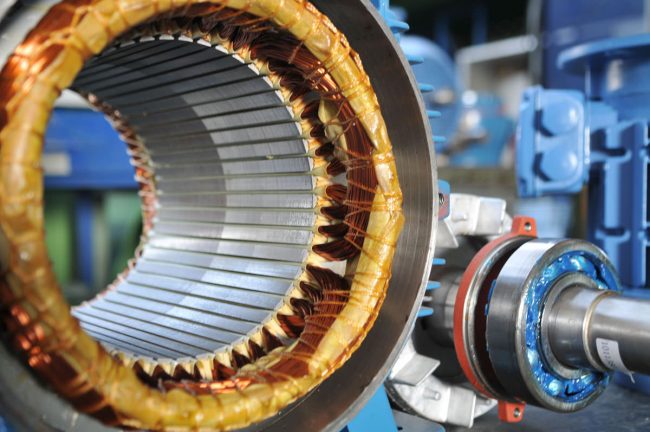

Actuators

COVNA offers a full port 3-way ss ball valve with an explosion proof electric actuator in thread, flange or tri-clamp style to fit your needs. The electric actuator is available in on-off or modulating type with bluetooth control, signal control and manual override. With a wide range of torque from 50Nm to 4000Nm, it provides the right amount of power to open and close your valves.

We offer both double acting and spring return pneumatic actuators for use in hazardous environments. These actuators feature two air supply ports with one driving the valve open and the other driving it closed, internally loaded springs then return the actuator to the original position.

Our ATEX approved OHQ series electric actuator is ideal for explosion proof applications. It drives the valve 0deg-270deg rotation and accepts a 4 to 20 mA current signal for positioning. It is suitable for petroleum, chemical, waler treatmenl, paper making, power plant and heating industries.

Installation

The three piece design of these full port sanitary ball valves allows for disassembly for regular cleaning. The valve ends are held in place through bolts so they can remain threaded into the pipe while the center section containing the valve body is removed for cleaning and servicing. This makes these types of valves a popular choice in the pharmaceutical, food and beverage industries for their easy disassembly and cleaning.

These stainless air actuated valves can be equipped with a fire safe fusible link, a pneumatic double acting actuator or an electric actuator. DA double acting actuators use the air supply to drive the valve open and closed with two supply ports, one driving the valve open and the other driving the valve closed. Spring return pneumatic actuators use internally loaded springs to close the valve when not under the influence of an external air supply pressure.

Electric actuated models use a 4-20mA input control signal to position the valve to a desired location within its range. They are available with a wide variety of supply voltages and with two-position or modulating controls.