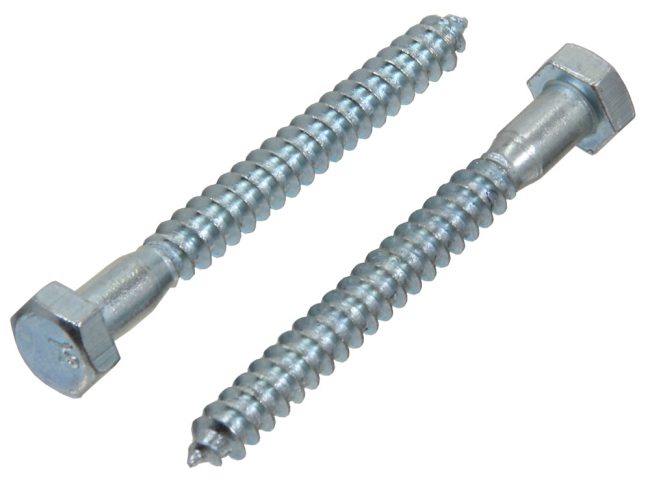

Lag bolts, also known as lag screws, are one of the most commonly used fasteners in various industries. They are designed to withstand massive forces that can be applied on lumber or other materials.

Like most other screw-in fasteners, a preexisting hole needs to be drilled before using a lag bolt. Choose a drill bit size that is slightly smaller than the bolt’s diameter.

Types

While some people use the terms lag bolts and lag screws interchangeably, they are actually two different kinds of fasteners. Bolts are used with a nut while screws are installed by rotating the head.

Lag bolts, on the other hand, are designed to be driven into wood with a wrench or hex driver. They are also more suitable for larger applications than wood screws, so you will need to have a pre-drilled hole to insert the bolt.

Lag bolts are commonly used to connect lumber together, but they can also be used to secure heavy materials like concrete and metal. These bolts are capable of handling significant amounts of stress, so it’s important to choose the right one for your project. The appropriate size can make or break your installation.

Applications

Lag bolts are used for a wide variety of carpentry projects. These include laying decks and building outdoor structures such as sheds or play equipment. They are also used for attaching metal components to wood surfaces.

While they are often referred to as bolts, technically they are screws. The hex head on these fasteners allows for higher wrench installation tension and helps them grip in wood better than regular nuts would.

Lag bolts are ideal for projects that require strong connections between two materials. They can hold up to nine times as much weight as a basic nail hammered into the same spot in wood. They can also be used for other hard materials such as metal and concrete. However, they must be pre-drilled into the surface before insertion.

Sizes

Lag Bolts come in a variety of sizes to accommodate different projects. They can also add a decorative element to any project with their unique head shapes and finishes.

Like other bolt fasteners, lag bolts have their own threads to make them more powerful and secure than other types of screws. They are able to penetrate wood materials with ease.

They are often used to attach something semi-permanently, such as wood beams to structures. They are driven into pre-drilled pilot holes and screwed in.

When choosing a lag bolt for your project, you should ensure that it is the correct size. It should be smaller than the combined width of the two pieces it is connecting. If you choose the wrong lag bolt, it could damage the materials or loosen over time.

Finishes

Like all fasteners, bolts and screws come in a wide range of strengths, materials, head shapes and finishes. Often, they are also classified by how much force they can bear.

Lag bolts, for instance, are used to handle massive forces. They are characterized by an unthreaded area on the shaft that produces huge compressive forces and can help keep materials together even when tightened.

Typically, they have a hex head that allows them to be gripped with a wrench or ratchet. Those used outdoors are often galvanized to protect them from corrosion. Moreover, they can be used in wood structures like backyard decks and playground equipment to connect and strengthen building materials. Alternatively, they are ideal for large home improvements and repairs like repairing a roof or building a new patio.

Decorative

Lag bolts, also known as lag screws, are extremely strong and versatile fasteners. They look like a large wood screw and are used to secure materials in carpentry projects such as deck building and framing.

They are especially useful for connections with heavier materials and can handle more force than other types of bolts and screws. This is due to their length, which gives them more gripping power and the fact that they create their own thread when penetrating soft materials such as wood.

They are also available in a wide variety of finishes, materials, and head shapes. Some of the most common include: zinc-plated lag bolts, stainless steel 18-8 lag bolts, and silicon bronze lag bolts. They can also be hot-dipped galvanized to increase corrosion resistance for use in outdoor applications.